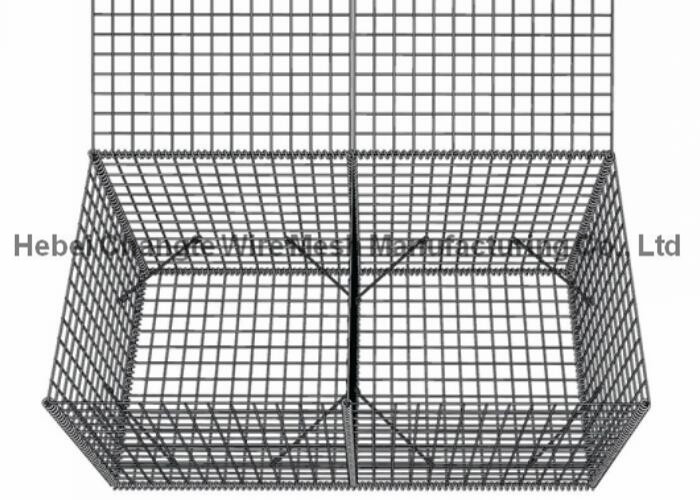

Welded Gabion Box

Welded Gabion Cage,Welded Gabion Mesh For Stone

Welded Gabion are made from rigid, lightweight, galvanized steel mesh thatallows for machine filling,

holds the alignment of the face.

Welded Gabion Material:Low carbon steel wire ; Galvanized wire

Nominal Box sizes | Mesh size | No. of diaphragms | Capacity per box |

1.0x1.0x0.5 | 50x50 | 0 | 0.50 |

1.0x1.0x1.0 | 0 | 1.00 | |

1.5x1.0x0.5 | 0 | 0.75 | |

1.5x1.0x1.0 | 0 | 1.50 | |

2.0x1.0x0.5 | 1 | 1.00 | |

2.0x1.0x1.0 | 1 | 2.00 | |

3.0x1.0x0.5 | 2 | 1.50 | |

3.0x1.0x1.0 | 2 | 3.00 | |

4.0x1.0x0.5 | 3 | 2.00 | |

4.0x1.0x1.0 | 3 | 4.00 |

Weldedgabion advantages:

Blends easily and harmoniously with the natural surroundings.

Low cost alternative to concrete or masonry structures.

Very high resistance to natural forces due to better tensile strength.

Can withstand any unpredictable movement or settlement without loss ofstability.

Simple and speedy installation, making it cost effective.

Quality finish and appearance is more aesthetically pleasing.

More rigid than woven mesh resulting in a more uniform finish when built.

Quicker and cheaper to install than Woven Mesh gabions because nopre-stretching required.

Special gabions sizes and mesh such as gabions with 4mm front mesh and 3mm meshelse can be available.

Application

1. Control and guide of water or flood

2. Preventing of rock breaking

3. Rock fall protection

4. Water and soil protection

5. Bridge protection

6. Strengthening structure of soil

7. Protection engineering of seaside area.

8. Port project

9. Keep off dust wall

10.Roadway protection.

How toinstall welded gabion ?

Step 1. Ends, diaphragms, front and back panels are placed upright on thebottom section of wire mesh.

Step 2. Secure panels by screwing spiral binders through the mesh openings inadjacent panels.

Step 3. Stiffeners shall be placed across the corners, at 300mm from thecorner. Providing a diagonal bracing, and crimped over the line and cross wireson the front and side faces. None are needed in interior cells.

Step 4. Gabion box filled with graded stone by hand or with a shovel.

Step 5. After filling, close the lid and secure with spiral binders at thediaphragms, ends, front and back.

Step 6. When stacking tiers of the welded gabion box, the lid of the lower tiermay serve as the base of the upper tier. Secure with spiral binders and add pre-formedstiffeners to exterior cells before filling with graded stones.

Company Name: Hebei Changte Wire Mesh Manufacturing Co.,Ltd | |

Address: East Development zone of Anping County, Hebei Province, China | |

Telephone: 0086-318-7997127 | |

Mobile: 0086-18931813303 | |

Contact Person: Cindy Song | |

E-mail: sale@hbct-wiremesh.com | |

Copyright © Hebei Changte Wire Mesh Manufacturing Co.,Ltd

网站备案/许可证号:冀ICP备14000901号-1